Joewell Technology

1. Size of scissors

The size of a scissor is usually indicated in inches. They range from 4.5” to 7.5”. The indication in inches is not the length of the blade but the length from the blade edge to the finger ring. Size is normally selected depending on the cut techniques and comfort of use.

Shorter scissors are more suitable for detailed work, longer scissors for powerful work. Cutting accurately in a straight line is the basis of the blunt cut and, therefore, the 5” to 6” sizes are more commonly used. The characteristics of long scissors enable efficient work because more hair can be cut at one time.

Shorter scissors are more suitable for detailed work, longer scissors for powerful work. Cutting accurately in a straight line is the basis of the blunt cut and, therefore, the 5” to 6” sizes are more commonly used. The characteristics of long scissors enable efficient work because more hair can be cut at one time.

2. Scissor Material

Blade Material is one of the most important elements in the quality of scissors.

To achieve a better edge and durability Joewell use the following original blade materials:

Supreme Stainless Alloy

This material was developed from the long-term experience in manufacturing techniques and the accumulation of user comments. It has the best edge sharpness and durability.

Cobalt Base Alloy

Cobalt Base Alloy is a mixture of components including chrome, tungsten and carbon, and does not require heat treatment, as the material already has hardness. Other characteristics include chemical-resistance and rust-resistance. Joewell uses two grades of cobalt base alloy. CBA #1 has higher hardness and longer life, and is suitable for dry hair. CBA #12 has lower hardness to enable a softer cut, and is a higher grade alloy Cobalt alloys have a higher wear resistance, stainless alloys have a greater hardness, giving a cobalt base alloy scissor a longer life.

Cobalt is not magnetic, therefore, you can determine between a cobalt base alloy and a stainless alloy by placing a magnet over the blade.

Heat treatment techniques

Heat treatment is applied to stainless blade materials. A computer controlled, vacuum heat treatment method is adopted. It can maximise the quality of the material and achieve consistent heat treatment. Joewell manufactures its products to a level of hardness that is 15% higher than most of its competitors, which produces the best edge and durability.

Heat treatment is applied to stainless blade materials. A computer controlled, vacuum heat treatment method is adopted. It can maximise the quality of the material and achieve consistent heat treatment. Joewell manufactures its products to a level of hardness that is 15% higher than most of its competitors, which produces the best edge and durability.

Handle Material

JOWELL use nickel-less (0.6% or less) stainless in most of our products to ensure against metal (nickel) allergies. Using a hard metal enables us to produce a very strong handle, making it dificult to damage or scratch.

3. Design of the handle

Select the most suitable handle shape depending on hand size, experience and cutting techniques.

Symmetric Handle

A Symmetric design makes it possible to use both sides of the scissors or to change the way the scissors are held for a greater degree of freedom.

A Symmetric design makes it possible to use both sides of the scissors or to change the way the scissors are held for a greater degree of freedom.

Offset Handle

The length of the handle grip differs between the still blade and moving blade. Offset handles easily fit the hand so the wrist, elbow and shoulder do not tire easily when opening or closing the scissors. It is especially easy and popular for the ordinary blunt cut. Another name for this is the ergonomic handle. Various angles and designs are available in offset and semi-offset types so please select according to preference.

Finger hole

Regular and Small sizes are available. A finger ring can be attached to reduce the size of the finger hole.

Regular and Small sizes are available. A finger ring can be attached to reduce the size of the finger hole.

4. Blade Shape

Blade Shapes

Joewell scissors are available in four blade shapes.

1. Standard Blade

The Joewell original standard blade is the most popular and easy to use. Incorporating a flat blade and light blade body enables us to provide a scissor, which is suitable for general use. Other characteristics include a flat face that fits the hair and comb face.

The Joewell original standard blade is the most popular and easy to use. Incorporating a flat blade and light blade body enables us to provide a scissor, which is suitable for general use. Other characteristics include a flat face that fits the hair and comb face.

2. Convex Pro Blade

In pursuit of sharp smooth cutting, this has the sharpest blade angle and setting. Craftsmen, to achieve the perfect finish, manually do final completion. Having a thicker blade shape makes the scissor more powerful, and with the point of the blade being smaller than a hair, hairs will not fly about.

3. Convex Shape Blade

Implementing the latest technology on top of the advantage of the convex blade developed the Convex Shape Blade. It maintains soft, sharp cutting and is suitable for anyone.

Implementing the latest technology on top of the advantage of the convex blade developed the Convex Shape Blade. It maintains soft, sharp cutting and is suitable for anyone.

4. Sword Blade

This type is a sword shape. The power is delivered to the point of the blade with this design

This type is a sword shape. The power is delivered to the point of the blade with this design

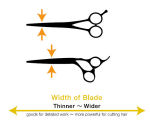

Width of Blade

Various blade widths are available. A wide blade is more powerful for cutting hair and the cut is light. A thin blade makes the scissor more suitable for detailed work.

Various blade widths are available. A wide blade is more powerful for cutting hair and the cut is light. A thin blade makes the scissor more suitable for detailed work.

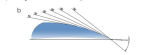

Blade Lines

Various blade lines are available. Generally, the straighter blade is called a straight blade, the ordinary one is called a willow blade, and the curved one is called a bamboo leaf blade. JOWELL designs blade lines according to the characteristics of each item. The straighter the blade, the easier it is to hold the hair for cutting without having the hair slide. The bigger the curve, the greater the amount of hair that will slide when cutting for a smooth soft cut. The bamboo leaf blade type, which has the biggest curve, is suitable for slide cuts and slicing.

Various blade lines are available. Generally, the straighter blade is called a straight blade, the ordinary one is called a willow blade, and the curved one is called a bamboo leaf blade. JOWELL designs blade lines according to the characteristics of each item. The straighter the blade, the easier it is to hold the hair for cutting without having the hair slide. The bigger the curve, the greater the amount of hair that will slide when cutting for a smooth soft cut. The bamboo leaf blade type, which has the biggest curve, is suitable for slide cuts and slicing.

5. Screw on the Scissors

Flat Screws will not hinder cutting because it has no bulge. Adjustable screws can easily be adjusted to suit your preference.

Precision Flat Screw

This is an ultra-precise NC manufacturing screw with little looseness. Because this screw is flat, it does not hinder the comb when cutting and can be adjusted with a coin (with 1.7 mm less thickness).

This is an ultra-precise NC manufacturing screw with little looseness. Because this screw is flat, it does not hinder the comb when cutting and can be adjusted with a coin (with 1.7 mm less thickness).

Thin Adjustable Screw

The fine screw thread in the 0.3mm size makes fine-tuning possible, and the locking and tensions functions prevent loosening. By embedding the screw, a more compact design was achieved.

The fine screw thread in the 0.3mm size makes fine-tuning possible, and the locking and tensions functions prevent loosening. By embedding the screw, a more compact design was achieved.

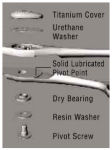

Dry Bearing Screw System

The dry bearing screw system is applied at the screw part to pursue opening/closing operation. The solid lubricated pivot point contact and the dry bearing are made of resin. The features are light, smooth opening / closing operation, maintenance free, lightweight and thin body.

The dry bearing screw system is applied at the screw part to pursue opening/closing operation. The solid lubricated pivot point contact and the dry bearing are made of resin. The features are light, smooth opening / closing operation, maintenance free, lightweight and thin body.

6. Removable Finger Rest

This is a finger rest with a washer, which does not easily come off. It is removable and easy to use. Finger shape was taken into consideration in the design.

This is a finger rest with a washer, which does not easily come off. It is removable and easy to use. Finger shape was taken into consideration in the design.

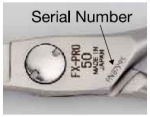

7. Serial Number

Each product has unique serial number, which is utilized for quality control and after-sales service management.

Each product has unique serial number, which is utilized for quality control and after-sales service management.